INSPECTION & WELDING OF LONG SEAM

In fabrication area

the fabrication of storage tank, pressure vessels etc. the plates is rolled and

make a joint as per required inside diameter of vessel or storage tank called

long seam.

The Typical Photograph of Long-Seam for information shown below,

PIC.01

The parameters which considered while inspection of Long

Seam is listed below,

1) First step of inspection of long seam is check

whether the long seam which plate is identified or not with inspectors stamp

and other job details like part no material grade etc.

2) Punching the seam

number along the seam at every 1000mm apart and highlighted also the seam no on

each seam.

3) Cleanness of Weld

Edge Preparation (WEP) and cleaning of nearest area of long seam & performing DPT (Dye Penetration Testing) on WEP as shown below,

PIC.02

4) All Tack Welds

free from cracks.

5) The Joint Details of Joint like Weld Edge Preparation

(WEP), Groove Angle Root Gap, Root Face is required to check as per engineering

Drawings or not.

6) Weld edge required

to check visually properly, free from arc strikes, spatters, gas cutting marks,

dent marks etc.

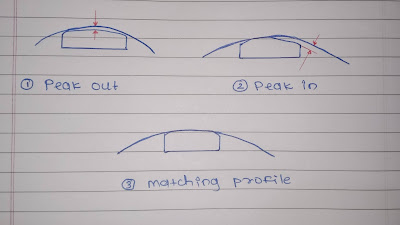

7) Profile Checking at Joint of Shell i.e.. At Long Seam Is

perfectly Matching with template profile or not, shown below,

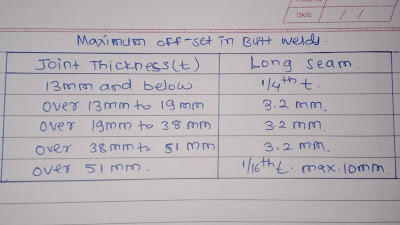

8) Check offset

within a limit or not. Shown below the typical Maximum Offset Limits below,

PIC.04

9) Running IN and OUT

coupons attached or not with matching Wels Edge Preparation. Shown below photograph,

PIC.05

10) PTC as

an extension to the seam if applicable (PTC : Production Test Coupon).Shown below the PTC attached with long-seam.

PIC.06

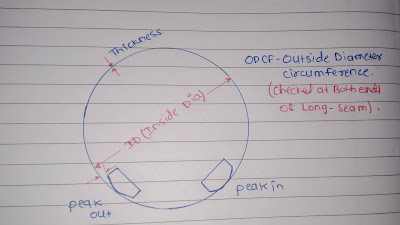

11) Profile Checking and Ovality checking which is within limit

or not.

12) Circumference at both ends of Long Seams is checked recorded

the value and checked with limit or not as per specification. Typical Diagrammatical view of Long seam with measuring parameter shown below,

PIC.07

WELDING OF LONG SEAM

1) Firstly, the seam is

inspected from inspection department.

2) Make preheat arrangement

if Preheat required and preheat the Long-seam edge at at temperature mentioned

in Specification (WPS/PQR).

3) Welding done as per

welding Test Plan (WTP). WTP consisting the welding paraments like type of welding,

type consumables/filler wires, Preheat, Inter-pass Temperature, Post Weld temperature

etc. Shown below Typical V Groove long seam set-up.

PIC.08

4) Performing Back-chip

DPT (Dye Penetration Test).

5) Maintain Weld

Reinforcement Within Limit (Tolerances as per specification) Typical Tolerances

of reinforcement for But Weld as per ASME SEC.8 DIV.1 UW-35 For Long-Seam shown

below,

PIC.09

6) Weld Seam free from visible Surface Defects

7) Re-Rolled the Shell if Shape is out.

8) Clear all NDT as mentioned in specification or in Weld And

Test Plan (WTP).

9) If applicable PTC proceed for Mechanical Testing and other tastings

as per requirements pensioned in Respective code or in specification.

ConversionConversion EmoticonEmoticon