HYDROSTATIC TESTING

Hydro-static testing is also called as hydro-test is the test in which

piping components, gas cylinders, storage tank, vessels etc is tested for the

leaks and strength of that component. The Hydro-static test is done after the

all activities like radiography of welding joints, required NDT, welding of all

pressure parts etc in order to the given object operate under desired

condition. This process in which the water filled in the component and

pressurised as per requirements of client which depend on service and other

factors.

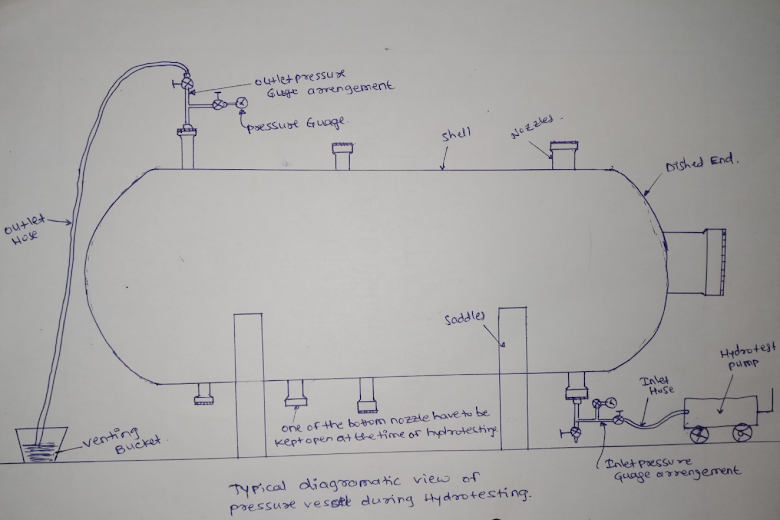

The Typical Diagram for

pressure vessel during hydrostatic test shown below,

The hydro-static test is performed by firstly filling the components

such as tank, pipes etc with water after filling removing the air inside the

component and after that pumping or pressurized by pump up to pressure of that

component mentioned on engineering drawing . After pressurized at component

hold at specific pressure for specific amount of time which depend on clients

criteria or approved hydrostatic procedure from client after holding period the

all weld joints and whole component is inspected with help of lamp for tracing

of liquid to determine the crack and any kind of leaks.

Hydrostatic test is plays very important role in inspection. The

pressure at which hydrostatic test to be performed is as per design calculation

of that particular object but normally 4 times of design

pressure.

One thing is noted that the Hydrostatic testing is the non destructive

testing method which used for testing leaks and performance of that component.

Every testing consisting certain type of procedure and the testing is

done as per the procedure. The pressure at which the hydrostatic test to be

performed is given in the engineering drawing the pressure is measure by

pressure gauge and the gauge should be in service & calibrated condition up

to date. The range of pressure gauge is mentioned in appropriate procedure, as

per ASME section viii code the required ranging is 1.2 to 4 times for example if the

components hydro pressure 32 kg/cm2 then the minimum range of

pressure gauge as per code 1.2 that means 1.2 x 32 is 38.4 kg/cm2 and

maximum range that is 4 x 32 is 128 kg/cm2 that means the

pressure gauge to be used is in between the range from 38.4 to 128 kg/cm2 .

Different types of hydrostatic tests perform as per

components and as per requirement as Direct Expansion Method, Proof Pressure

Method, Water Jacket Method etc. But basic procedure is same. For example if we

performing the hydrostatic test of pressure vessels then the following points

must be consider in inspector point of view as,

1) Proper blanking of all Nozzles.

2) All Original blind flanges used Properly or not.

3) Completion of welding on pressure parts.

4) Vessel is kept on hydrotest saddles in the specified orientation as

per engineering drawings issued by design department.

5) Clearance of all pending NCR’S (Non Conformity Report) if any.

6) All Long Seams / Cir-seams are more visible for inspection.

7) Gaskets and gasket seats checked for any damages.

8) Inside surface properly clean or not.

9) Testing of PTC/MTC If any to the acceptable test results.

10) Check outside diameter circumference (ODCF) before pressurized, during pressurized and after release of pressure ODCF values is to

be reported.

11) All weld joints to be visually checked with lamp or

apply DPT testing on Weld joints.

12) Ensure that for original blinds the original fasteners

provided or not with required material grade and tightened to required torque

or not.

14) The water used is portable or other. (As per

procedure)

15) Measure the Metal temperature of vessel before Hydrostatic test.

16) Exact Ranging of pressure gauge is used or not.

) 17) Pressure gauges calibrated during the service and calibration certificate of calibration agency.

18) Arrangement for pressuring shall be through one of the nozzle for bottom.

19) Hydro Pump for pumping of water is available or not.

20) Inlet valve shall remain closed till water filling.

21) And most important parameter that is all activities like str Heat

treatments stress relieving (S.R.) if applicable is done or not, required NDT

performed or not in other word all required activities as per approved QAP.

After the hydrostatic test the Hydrostatic test Report is prepared as

per procedure the positioning of component, acceptance criteria, test

temperature, pressure application, type of inspection, rejection and

documentation all mentioned in approved procedure.

Acceptance Criteria.

For Section VIII Division 1 type

Pressure Vessels Reduce the test pressure above design pressure and inspect all

joints for leackage (As Per UG-99).

Design Pressure x 1.3 x Ratio of stress value of material at test temperature to Design Temperature.

For Section VIII Division 1 type

Pressure Vessels Reduce the test pressure above design pressure or 3/4th

Test pressure whichever is more and inspect all joints for leakage (As Per AT-355 & at-300 ).

Design Pressure x 1.25 x Ratio of stress value of material at test temperature to Design Temperature.

If any leakage

is observed from weld or parent metal or any joint, drain the water repair the

leak and reoffer for the hydrostatic testing.

If any leakage

observed through Gasket connection, depressurized the vessel and tighten the Stud/Nuts.

Arrangement of Inlet

pressure gauge & arrangement of Outlet pressure gauge as shown below,

Pic.02 : Arrangement of Inlet Pressure Gauge.

Safety points :

1) Drain

the water from vessel only when top outlet is kept open.

2) Never

pressurised vessel above required or mensioned pressure in given engineering drawings.

3) Use

minimum 2 pressure gauges for hydrotest.

4) Never use High discharge pumps for hydrotest.

ConversionConversion EmoticonEmoticon