ALIGNMENT CHECKING

Basically, arrangement in s straight line

is called as alignment

1 1) Axis Alignment.

2 2) Surface Alignment.

1) AXIS ALIGNMENT:

The axis

alignment used for pressure vessel, column, storage tank for proper straightness

of whole job. Axis Alignment is checked with axis of job. The axis alignment

checked on respective four orientation of vessel by rotating the shells of vessel.

In axis alignment measure the perpendicular distance between plumb line and

horizontal line (See Pic.001) and record.

Diagrammatical

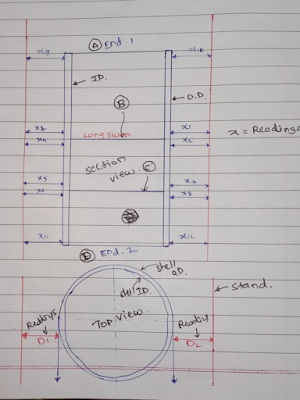

view of checking of Axis Alignment as shown below,

Pic.001

The reading record

as per table shown below,

Pic.002

The axis alignment

of vessel check by following method,

1) Firstly, plot the points on Graph paper

with suitable scale

2) Draw the best fit line to pass through all

points on graph.

3) The maximum distance measured from the line

is the maximum Out of Alignment.

4) Find

out maximum out of alignment in both the planes and note as (A) 0-180 Degree.

Readings 90-270 degree. Readings

Pic.003

5) Repeat the process for the same 90-270-degree orientation by rotating the

shell of vessel

2) SURFACE ALIGNMENT:

The typical example of measurement of vessel dimensions for surface

alignment as shown below,

Pic.004

The method of checking surface alignment as shown below,

1) Firstly, level the shell at

main degrees orientation (0,90,180 & 270 Degrees) vertically or

horizontally.

2) Drop the pair of plumbs near

each Circular seam and on both ends.

3) Put twins horizontally on both sides of shell.

4) Maintain equal distance at both

ends of sections between horizontal twins and plumb.

5) Then measure the perpendicular distance between other plumbs and horizontal twins and records the reading in table (See Pic.005) as shown below,

6) Rotate the job 90 degree and repeat the same process for the other orientations and record the readings.

Surface Alignment = Maximum

Reading – Minimum Reading.

Pic.005

Surface alignment for different

shell Thickness:

The dimension settings at

ends and decided taking in to consideration of shell thickness (See Pic.006)

and for remaining repeat the same procedure.

Pic.006

Important Note : The shell or ovality of the shell shall be controlled within the limit in order to get better alignment of Job.

ConversionConversion EmoticonEmoticon