HARDNESS TESTING.

The

hardness test is mechanical test which used to check the hardness of material,

Resistance of a material to permanent deformation as indentation wear etc

called hardness.The hardness of material depends upon tensile/yield

strength,grain size etc.

- Rockwell Hardness.

- Brinell Hardness.

- Vickers hardness.

- Shore schlerescope.

In

a pressure vessels generally after PWHT (Heat Treatment) the hardness testing

carried out by the technician. The requirement of hardness checking on WELD or

HAZ area inside the vessel or outside of vessels depends on client

requirements. The hardness checking tester calibrated by standard calibration

block before checking of hardness and the block should be calibrated in

specific interval of time.Calibration certificate is required for review.

- Brinell Hardness -

This type of

hardness checking for soften material like mind steel, low carbon steel,

aluminium or copper etc. The main principle of this type of hardness based on

area of penetration area. In this type of hardness testing the 3000 kg is

applied on indental ball of (10 mm dia) for 10 seconds.

Brinell hardness calculated by formula,

- Rockwell Hardness -

This hardness technique is most widely used due to

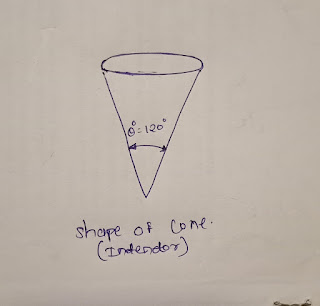

easiness similar to Brinell technique. In this type of hardness technique the

indentation tool used made up of diamond material,shape of the ball is

conical.The Rockwell hardness check for all materials except some very hard

material. The main principle of this technique is based on depth of penetration

of ball.

One thing is noted that the Rockwell hardness value is

inversely proportional to depth of penetration as the more depth of

penetration of ball,hardness value is less and vice-versa.

- Vickers Hardness -

This

technique is similar to Brinell test as the tool material used for

indentor is made up of diamond. The shape of indentor tool is pyramid with base

is in square shape and angle between apposite edged is 136 degrees. The main

principle of this technique is diagonals of indentor is left on the

surface of material. Vickers hardness calculated by following formula,

For hardness checking of high carbon steel or tungsten carbide this technique is used.

- Shore schlerescope -

In

this technique the diamond ended hammer is falls inside the glass tube

under the specific amount of force (own weight of hammer also)from fix specific

height on the material,when the hammer is rebound the height of rebounded hammer

is measured on graduate scale, this scale is consist of 100 parts, this scale

may increase when the material having high hardness.

The value of schlerescope hardness is depends upon the rebound of

hammer so as a material is harden then more the hammer rebound and

the height of rebounded hammer is more so that readings is taken.Main

advantage of this type of technique is portable.

If

workman is trained for operation of this hardness then this hardness checking

technique is easy.

ConversionConversion EmoticonEmoticon